- Home

- Blog

- Noise-Induced Hearing Loss

- Hearing Loss in Mining: A Muffled Safety Concern for Nearly 30 Years

Hearing Loss in Mining: A Muffled Safety Concern for Nearly 30 Years

Mining presents many risks to all involved, from the financial and investment level, down to the frontline worker in the mines. In the public's mind, the risk of a mining shaft cave-in far outweighs the risks to physical health over time. When health risks are discussed, it has commonly only been about diseases such as black lung disease. However, according to the CDC, "One out of every four mine workers has a hearing problem. Even worse, four out of five mine workers have a hearing impairment when they reach mid-60s retirement age" (Centers for Disease Control and Prevention, 2018). Furthermore, 76% of miners are exposed to hazardous noise daily, which is more than any other major industry.

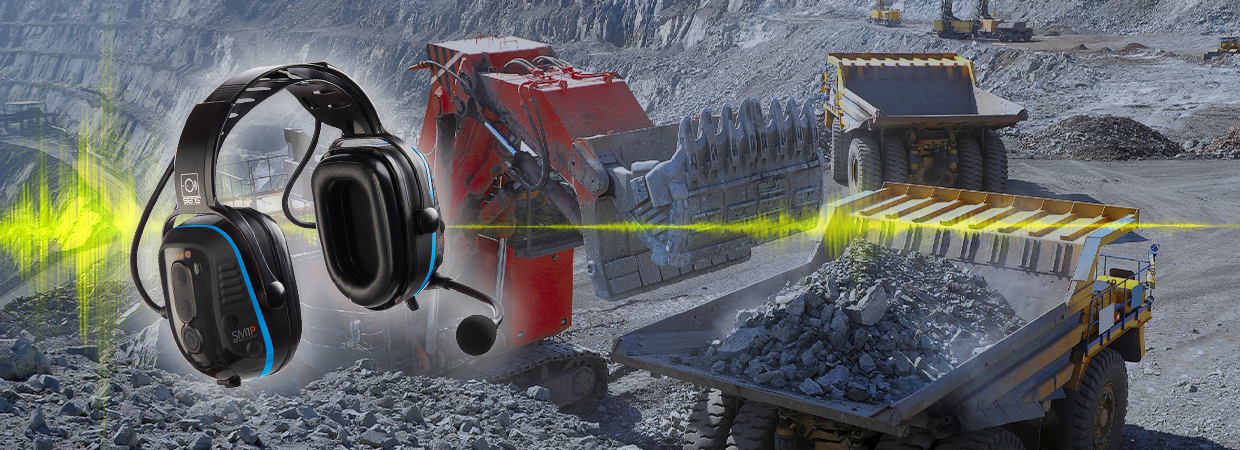

In the mining industry, workers face many occupational risks, noise-induced hearing loss (NIHL) being chief among them. Working constantly next to heavy, loud equipment like conveying systems, drills, and other machinery should be enough to motivate mine workers to wear hearing-protective gear. But many workers do not, and subsequently suffer some form of hearing loss. There’s no question that the mining industry is filled with high noise that requires hearing protection devices (HPDs) for workers to perform safely. But when traditional HPDs interfere with worker communication, the devices are often removed so that workers can talk to one another, exposing them to the risk of hearing loss the HPDs were intended to prevent. This risk may be best summed up by the CDC, which features a paper on its website from the Noise Control Engineering Journal that states:

"[M]iners frequently complain of reduced audibility or confusion about identifying spoken words when wearing conventional hearing protectors. This leads to an increased risk of miners being struck by moving equipment or errors in communication with co-workers. Miners will often remove their hearing protectors to overcome these obstacles.”

Obviously, this is an issue and can directly lead to permanent hearing loss. Mining employers need a solution for the risks of hearing loss in mining and other challenges such as communication and safety.

Examining the Challenges of a Mining Environment

A study by NIOSH in 1996 found that an estimated 90% of miners worldwide have developed hearing impairment by the age of 50 (NIH, 2018). Despite there being nearly 30 years of hazardous occupational noise regulation within the mining industry, noise-induced hearing loss still remains an issue. A whopping 80% of American miners work in an environment where the time-weighted average (TWA) noise levels exceed 85 dB(A). Moreover, 25% of these miners are exposed to TWA noise levels that exceed 90 dB(A).

Heavy-duty equipment, such as long-wall shearers and pneumatic percussion drills are commonplace within a mine and present significant noise-related mining hazards. Noise levels can exceed 105 dB(A) around this equipment, sometimes peaking at 140 dB(A), and traditional hearing protection doesn’t allow workers to hear the equipment to listen for any potential issues. To accommodate for the noisy environment, workers are often forced to move to a quiet area, or they rely on the use of hand signals to communicate issues.

Whether a worker is in the cab of a haul truck, operating a front loader, underground, or in the control room, communication with the rest of their team is critical. In these situations, workers may not have line-of-sight visibility to their co-workers, so two-way radios or mobile phones are often the standard means of communication.

High noise is not the only challenge faced when it comes to communicating with co-workers. Mines provide a very harsh environment that often requires not only the use of hearing protection but also respiratory protection. Without proper communication tools, workers are forced to remove their respirators to communicate which results in lost productivity and exposure not only to high noise but also to hazardous materials.

How Sensear Unifies Hearing Protection and Communication into One Solution

In an ideal world, the solution to NIHL would be to reduce the noise in the workplace. While advances in technology and increased awareness of the dangers inherent in high-noise mining environments have led to reductions in equipment operating noise, there is no way to bring the noise levels of mining operations to a point where hearing protection is not required. Until that day comes, the mining industry needs a hearing protection and communication device that allows workers to hear one another, stay fully aware of their peripheral surroundings, and remain protected from dangerously high noise levels.

Sensear's Smart Industrial Communication Headsets and Earplugs provide optimum noise suppression with full 360° situational awareness and communication. This is accomplished with our unique SENS® Technology, taking noise cancellation to a whole new level. By isolating and enhancing speech while reducing harmful background noise, SENS® allows users to hear speech and stay protected while remaining aware of their surroundings in high-noise environments.

When working in mining, there are certain safety requirements that must be met to use the equipment. These environments are explosive atmospheres where intrinsically safe products are required. Intrinsically safe headsets must stand up to and pass a rigorous set of standards put forth by experts in the field of safety. Sensear’s Hazardous Location Headsets are certified by all four major intrinsically safe standards (ATEX, UL, CSA, and IECEx).

Furthermore, the Mine Safety & Health Administration requires miners to wear double hearing protection when noise exposure equates to greater than 105 dB(A). The advisory and research board backing OSHA has an equally strong recommendation, stating that those who work in environments that are 100 dB(A) and more should wear dual protection. Our Extreme Noise Headsets incorporate our unique dual protection feature and offer a total communication solution for hazardous and extremely loud environments, with a noise reduction rating of 36dB NRR.

To see a real-world example of how proper equipment and implementation can make a difference in the mining industry, download our case study of how Gold Fields – St. Ives Gold Mine has benefited from our smart two-way radio headsets. Also, look at our smart headsets helping miners in Peru protect their hearing and remain situationally aware while communicating via their radio system in an environment with over 100 dB(A) of noise:

Sensear’s high-noise communication specialists excel at helping customers find the right solution to their specific hearing protection needs. They understand that the global mining industry is a diverse and dynamic workplace and are prepared to offer several custom implementations. Contact us today!