- Home

- Blog

- Hazardous Locations / Intrinsic Safety

- What Do All Those Hazardous Symbols and Markings Mean?

What Do All Those Hazardous Symbols and Markings Mean?

In the previous blog, we discussed how to know whether your industrial headsets are intrinsically safe, and we briefly introduced what it means to be intrinsically safe. As we learned, intrinsically safe products, or headsets, in this case, are meant to keep the user safe when in explosive or hazardous environments. In this blog, we will dive deeper into what these hazardous environments look like and how they are systematically classified into different classes, divisions, zones, etc.

Explosive Protection Classification Systems

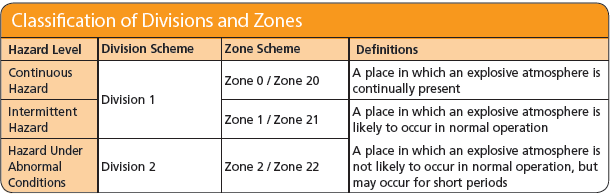

A hazardous location is where an explosion or fire can occur due to the presence of flammable gases or other combustible vapors. Hazardous locations are classified by the likelihood of combustible material igniting in a concentrated area. In North America, there are two explosive protection classification systems in place: the Division system and the Zone system. There are two divisions and three zones, which are as follows:

Effectively, the only difference between divisions and zones is that divisions do not differentiate between continuous and intermittent hazards, whereas zones do. However, they are similar in that the lower numbers correspond with higher hazard levels. Within divisions and zones, there are also three different hazardous location classes, which are Class 1, Class 2, and Class 3, respectively:

- Class 1 – The hazard is a flammable gas, vapor, or liquid

- Class 2 – The hazard is a combustible dust

- Class 3 – The hazard is an ignitable fiber or flying

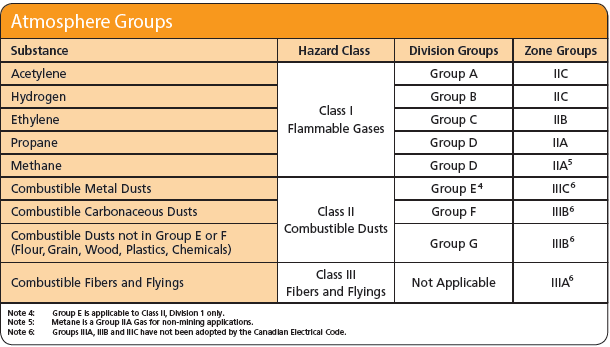

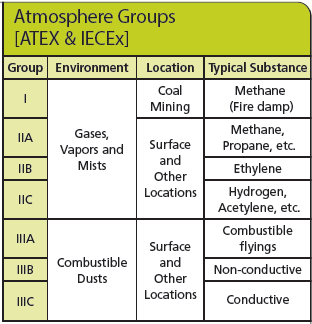

Now, each Hazard Class has different Division Groups and Zone Groups associated with them, which are broken down in the table below:

Like the Division and Zone schemes, the highly flammable gasses and substances are associated with the lower classes and groups. Although it looks complicated, this chart helps determine just how dangerous a substance can be and exactly what protection is needed.

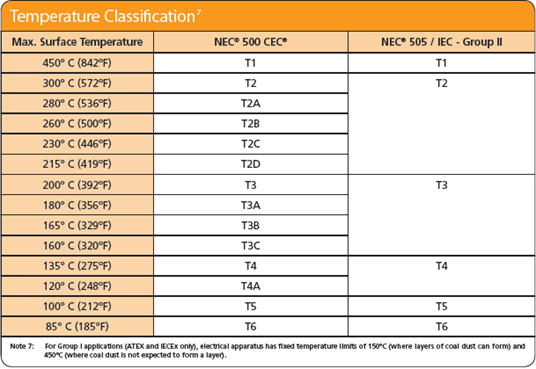

While gases and vapors are classified into Gas Groups, hazardous equipment is classified either by maximum (spark) energy it can produce (Apparatus Group) or by maximum surface temperature (Temperature Class). Temperature classification is broken down in the table below:

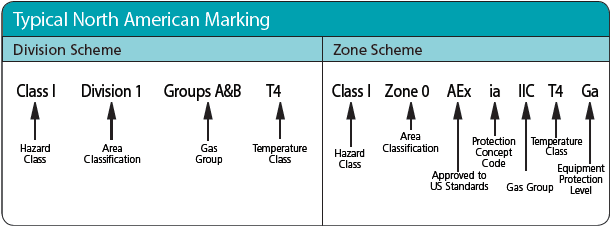

Below is a typical North American Marking for both the Division and Zones schemes:

Now, you may see a couple of markings in the Zone Scheme that are still unfamiliar. This is because Europe operates in the Zone scheme, and there are some ATEX and IECEx symbols mixed in. For ATEX and IECEx, there are two classification systems, which are self-explanatoryly called Group I and Group II. Group I contains the underground parts of mines and surface installations of mines that may contain methane and/or combustible dust. Group II contains all other industries.

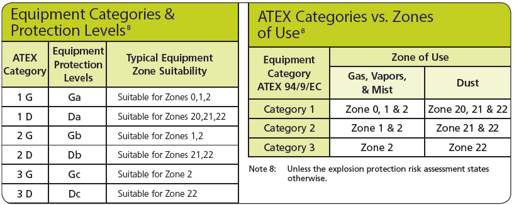

While ATEX and IECEx are very similar to North America, they have slightly different Atmosphere Groups and Equipment Groups/Categories & Protection Levels:

![]()

These ATEX categories correspond with the Zone scheme from above, and the Atmosphere Groups are similar to the North American Hazard Classes, only differing by combining combustible flyings into the same category as Combustible Dusts. Furthermore, the Equipment Protection Levels label which Zones certain equipment are suitable for, depending on the flammability of the environment.

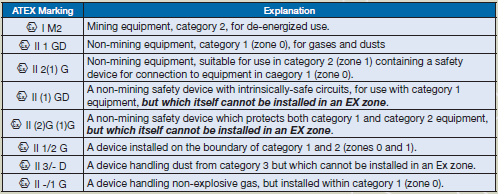

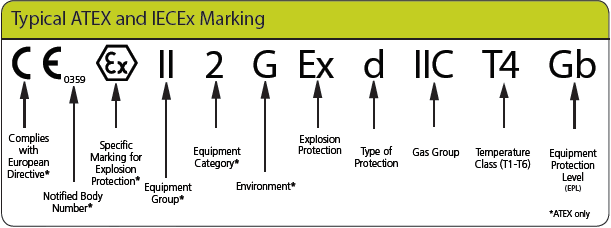

ATEX and IECEx also differ majorly from North American markings (such as CSA or UL) in that they also require ATEX markings that represent different equipment. Here is the breakdown for the ATEX markings:

Although these are self-explanatory, they are very specific and require careful labeling on your Intrinsically Safe products. Here is a typical ATEX and IECEx marking:

Sensear’s Certifications

So, how do you know the communications headset that you have chosen is Intrinsically Safe for your work environment? The design of the communication headset will determine its rating and will be labeled with the appropriate Hazard Class, Area Classification (Zone), Gas Group, and Temperature Class.

Sensear’s Intrinsically Safe headsets are certified to meet the global standards of ATEX, IECEx, UL, CSA, and TIA. For North America, Sensear’s IS headsets and smartPlugs™ are rated Class 1 (rated for flammable gases, vapors, or liquids), Division 1 (continuous and intermittent hazards), with UL 913/FM 3610 and CSA C22.2 No. 157 certifications. For ATEX and IECEx, Sensear’s IS headsets are rated Ga (suitable for Zones 0,1,2), Gb (suitable for Zones 1,2), and Gc (suitable for Zone 2) for gases, vapors, and mists, as well as Da (suitable for Zones 20,21,22) and Db (suitable for Zones 21,22) for combustible dust.

With these certifications, Sensear’s IS headsets and smartPlugs™ achieve the highest standards of IS industrial headsets for use in harsh environments like mining, oil, gas, or steel mills.

Want to learn more about how our Intrinsically Safe headsets can benefit your workplace? Contact one of our high-noise communication specialists today. You can also use our headset selector tool to determine which of our Intrinsically Safe hearing protection devices is right for you.