- Home

- Blog

- Noise-Induced Hearing Loss

- How to Prevent Noise-Induced Hearing Loss in Manufacturing

How to Prevent Noise-Induced Hearing Loss in Manufacturing

Is Occupational Noise Induced Hearing Loss Really a Challenge for Today’s Manufacturer?

Occupational Noise-Induced Hearing Loss (NIHL) is a significant concern worldwide. According to the National Library of Medicine, it is the most prevalent occupational disease globally. The U.S. Centers for Disease Control and Prevention (CDC) states that approximately 46% of all workers in manufacturing have been exposed to hazardous noise. Furthermore, about 20% of noise-exposed manufacturing workers suffer from a hearing impairment that impacts their daily activities and increases their risk.

According to the U.S. Bureau of Labor Statistics, over 72% of recorded occupational hearing loss claims in the U.S. occur in the manufacturing sector. This highlights a critical issue: many workers suffer from occupational hearing loss but cannot substantiate their claims. For a claim to be recorded by OSHA, the hearing loss must be work-related and severe enough to cause impairment. The CDC estimates that compensation for occupational hearing loss in the US alone exceeds $242 million annually.

What Can You Do to Protect Yourself from Noise-Induced Hearing Loss in a Manufacturing Environment?

Employers and safety professionals have a responsibility to protect workers from multiple hazards, including noise and hearing loss. Despite being less recognized than other injuries, hearing loss is a gradual process and not immediately noticeable. Repeated exposure to high noise levels, such as working near machinery or heavy equipment, can lead to permanent hearing loss or tinnitus.

The U.S. Occupational Health and Safety Administration (OSHA) requires employers to provide hearing protection when noise exposure equals or exceeds an 8-hour time-weighted average (TWA) of 85 dB(A). Hearing Protection Devices (HPDs) are highly recommended to minimize noise exposure and prevent hearing loss in the manufacturing industry. However, before you consider foam earplugs as an affordable solution, it's important to think again.

Foam earplugs might increase the safety risks for your workers on the job. Researchers at Johns Hopkins School of Medicine report hearing loss can exponentially increase your chances of falling. The odds of falling increase by 140% for every 10 dB of hearing loss. With foam earplugs, you are not only reducing the employee’s hearing, but you are potentially increasing their risk of falling on the job.

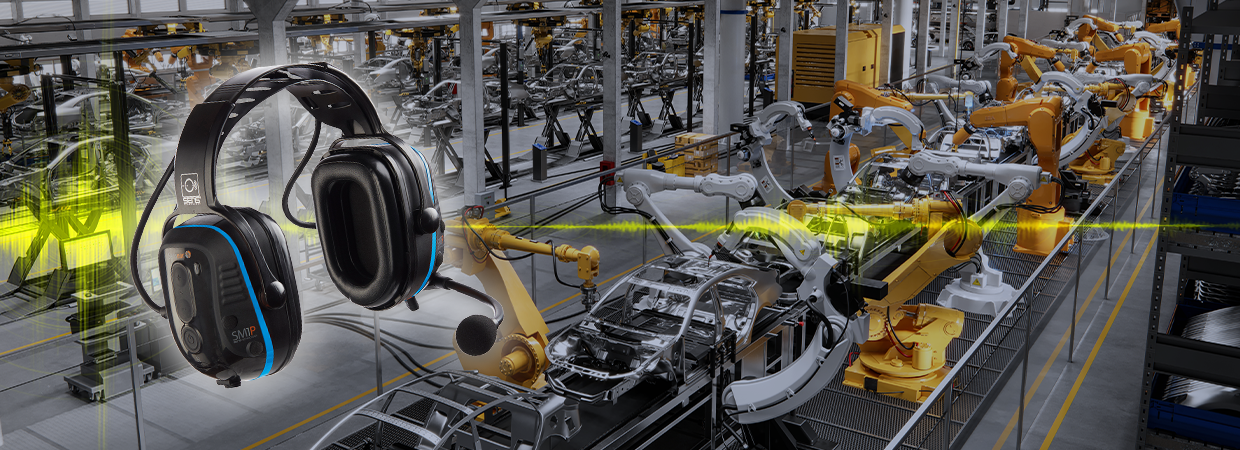

Hearing Protection Devices for Manufacturing Plants

Incorporating safety measures such as eliminating noise at the source and isolating workers from the noise source can help reduce exposure. However, using HPDs along with these precautions is essential for controlling noise in manufacturing plants. Various HPDs are available, including headsets for communication and safety, Dual Protection Headsets for exposures exceeding 100 dB(A), and in-ear bone conduction earplugs suitable for workers who need to wear respirators but still require effective communication.

The Importance of Enhancing Communication and Hearing Protection

Reducing high noise levels to safer decibel levels is crucial for protecting manufacturing workers. Ensuring workers have 360° situational awareness of their environment enhances overall safety on the job. Noise-canceling boom microphones and advanced technologies can help workers communicate effectively, even near heavy machinery, without compromising on hearing protection.

Solutions for Today’s Connected Worker

Today's connected workers need to stay in touch with colleagues whether they are nearby or communicating remotely. Advanced communication solutions, such as integrated FM frequency headsets, two-way radios, and Bluetooth® streaming devices, can facilitate effective communication in high-noise environments.

Working in Hazardous Locations

Hazardous locations, where explosions or fires can occur due to flammable gases or combustible vapors, such as dust from paper pulp, grain feeds, chemicals or other particles, require intrinsically safe solutions. Hazardous locations are classified by the likelihood of combustible material igniting in a concentrated area. Intrinsically safe headsets and earplugs are certified to meet global standards (ATEX, IECEx, UL, CSA, TIA, etc.), ensuring the highest safety for workers in hazardous manufacturing environments.

Finding the Right Solution for Your High Noise Problems

Addressing high-noise communication problems in manufacturing facilities involves finding the best hearing protection solutions that enhance communication, suppress noise to safe levels, and maintain situational awareness. By implementing proper controls and providing adequate protection, work-related hearing loss can be prevented.

Sensear is solving high noise communication problems for many of the world’s leading manufacturing facilities and segments including heavy and light manufacturing, industrial, automotive, transportation, steel, paper, lumber, bottling, food processing, grain/feed, chemical, textile, pharmaceutical, distribution centers, warehousing and more.

Occupational hearing loss is a preventable injury when proper measures are taken. While hearing damage cannot be undone, proactive steps can safeguard employees and reduce the risk of noise-induced hearing loss. Investing in effective hearing protection and communication solutions is essential for maintaining a safe and productive manufacturing environment. Let Sensear solve your high-noise communication challenges and safeguard your employees. Schedule a free consultation today, and we’ll help you find the ideal hearing protection solution for your facility.