Hearing Protection and Communications Solutions for Food Processing

Food processing is vital to the global economy and feeding an ever-expanding population, but it is also an industry with pervasive health and safety hazards.

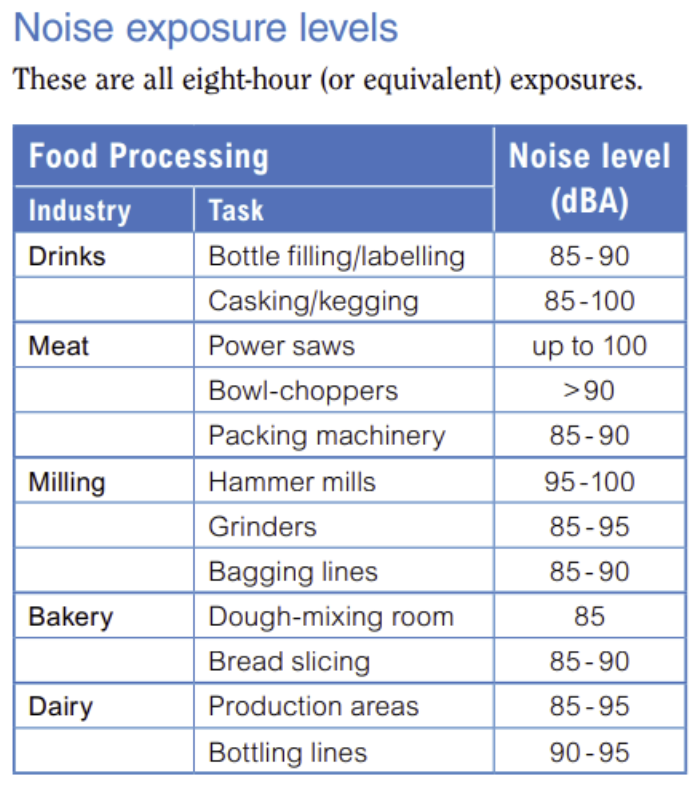

One significant hazard frequently overlooked for employees in food processing plants is the noise from processing machinery. The high-end noise emitted from food processing machines like meat grinders, blenders, mixers, choppers, packers, conveyors, assembly lines, and more can put employees at risk for noise-induced hearing loss.

According to the Bureau of Labor Statistics, “Hearing loss rates are almost twice as high in food production than manufacturing overall, with some sectors particularly noisy. Workers in breakfast cereal manufacturing, for example, experience hearing loss at a 30.9 rate. Sugar production workers have a 33.2 rate. Animal slaughter, excluding poultry, is even higher, at 68.2. Frozen fruit, juice, and vegetable employees have a 46.1 rate.”

There are over 1.64 million workers in the food processing industry who face numerous safety hazards while on the job. One of the most common hazards is the high noise levels from the equipment around the plant. In certain food processing plants, the noise can exceed 95 dB(A), making it difficult for workers to communicate effectively.

Multiple hazards exist for food processing workers on the job; however, noise and hearing loss is not typically considered as being as critical dangers like slips, trips and falls. Because hearing loss is more gradual and not typically immediately noticeable, it is less recognized than other injuries.

Hearing damage is preventable, but it cannot be undone. There is no surgery or cure for noise-induced hearing loss. Repeated and sustained exposure to high noise levels, such as working near machinery, operating blenders, and mixers or near conveyor lines, can lead to permanent hearing loss or tinnitus.

Sensear is Solving High-Noise Communication Problems in the Food Processing Industry

The U.S. Occupational Health and Safety Administration (OSHA) requires manufacturing industry employers to provide hearing protection to their employees when noise exposure equals or exceeds an 8-hour time-weighted average (TWA) of 85 dB(A) or more.

There are a variety of different machines, equipment and activities within food processing that can create significant and harmful noise levels, particularly with long-term exposure. In addition, some food processing processes require intrinsically safe headsets as dust particles such as flour can be explosive in the air or if allowed to build up on equipment. That is why providing workers with the proper Sensear noise-cancelling headsets is critical to mitigating the serious risk of hearing loss.

Hearing Protection Headsets and Noise-Cancelling Communication Headsets for Food Processing Workers

Reducing high-noise levels to safer decibel dB(A) levels to protect manufacturing workers is only part of the mission at Sensear to keep workers safe on the job. In addition to our industry-leading noise-reduction headsets, we also provide workers with 360° situational awareness of their environment.

Sensear’s range of Two-Way Radio and/or Bluetooth® Wireless Technology Headsets and Earplugs are powered by groundbreaking SENS® (high noise communication) Technology that elevates speech and suppresses dangerous background noise, so workers can hear speech and stay protected in high-noise environments. The result is increased job site safety with enhanced communications and vital 360° situational awareness.

Heavy-Duty Food Processing Headsets for Hearing Protection and Communication

Sensear offers a variety of headset solutions to provide the best protection so your workers can communicate safely and clearly, including dual-protection headsets where exposures may exceed 95 dB(A), intrinsically safe headsets for volatile environments, and in-ear bone conduction headsets that are ideal for workers required to wear respirators, but who still need to communicate effectively.

With some of the best hearing protection solutions for food processing applications, Sensear is solving high-noise communication problems for many of the world’s leading food processing manufacturers:

Find the Best Manufacturing Headsets for Hearing Protection and Communication

To get the best solution for communication, speech enhancement, and noise suppression for food processing, schedule a free consultation today, and we’ll help you find the ideal hearing protection solution for your facility.

Food Processing Blogs

Support Documents

Sensear in Action:

In Food Processing Industry

Food Processing plant workers can now communicate safely and clearly in high noise (98dB), using Sensear headsets with their existing Two-way radio system.